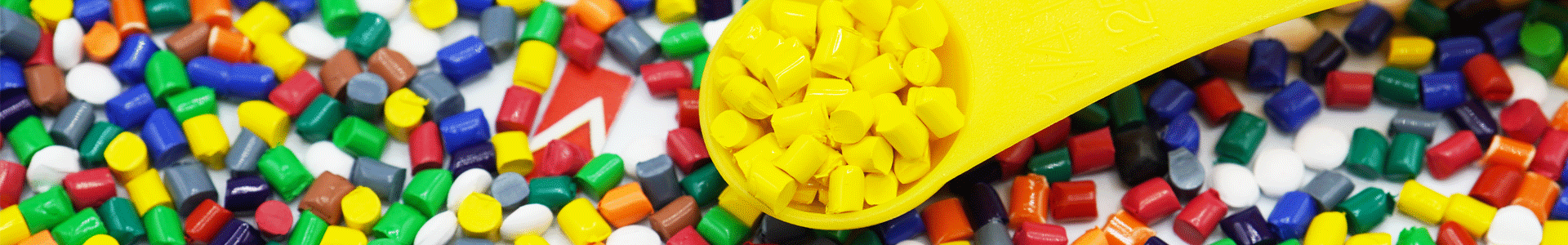

White Masterbatch: Transforming Plastics with Superior Performance and Versatility

2025-03-02 01:53:28In the ever-evolving plastics industry, efficiency, versatility, and cost-effectiveness are paramount. White masterbatch, primarily composed of titanium dioxide (TiO₂), has emerged as a key component, offering a range of benefits that make it indispensable across various applications. This article delves into the advantages, industrial uses, and in-application benefits of white masterbatch, highlighting its significant impact on the plastics industry.

5 Key Benefits of White Masterbatch

White masterbatch, made with TiO₂, offers several critical benefits that enhance plastic products:

1. Chemical Stability

When TiO₂ selection, dispersion, and loading are carefully monitored, white masterbatch ensures the chemical stability of pigments, resulting in high-quality and durable plastic products.

2. Ease of Incorporation

White masterbatch is easy to use and compatible with multiple resin carriers. It disperses uniformly without affecting processing characteristics, requiring no special safety measures or storage conditions.

3. Superior Pigmentation

White masterbatch provides vibrant and consistent coloring, maintaining a bright, pure white appearance. Its excellent pigmentation ensures color consistency and resistance to fading over time.

4. Thermal Stability

TiO₂ offers high thermal stability, preventing degradation under processing conditions. This enhances the lifespan of products by maintaining structural and functional properties at elevated temperatures.

5. Customization

White masterbatch is a cost-effective solution for achieving specific brightness and performance requirements without additional dyes or pigments. It can be tailored to meet diverse industry needs, such as packaging, automotive, and pressure pipes.

Top 3 Industrial Uses of White Masterbatch

White masterbatch is widely used in three main industrial applications due to its exceptional properties:

1. Packaging

White masterbatch is commonly used in packaging materials such as bags, films, and containers. Its clean, bright appearance and decontamination properties make it ideal for food packaging.

2. Automotive

In the automotive industry, white masterbatch is used to produce visually appealing and durable components like dashboards, trims, and door panels. Its resistance to heat, weather conditions, and degradation, along with RoHS compliance, makes it a safe and environmentally friendly choice.

3. Medical Industry

White masterbatch is used in medical equipment production due to its antibacterial properties, consistent coloring, and clean appearance. It is commonly used in syringes, medical tubing, and IV bags.

2 Great In-Application Uses

1. Injection Moulding

White masterbatch is highly compatible with carrier materials and plastic species, ensuring excellent dispersion during heating. It enhances properties such as brightness, consistency, and UV resistance, making it ideal for injection moulding applications like shells and containers.

2. Blow Moulding

In blow moulding, white masterbatch enhances thermal stability, preventing plastic degradation under high heat. Its pellet form allows for easy feeding into the hopper, ensuring great dispersion and color consistency.

Conclusion

White masterbatch is a versatile and essential component in the plastics industry, offering numerous benefits such as chemical stability, superior pigmentation, and thermal resistance. Its applications in packaging, automotive, and medical industries, along with its use in injection and blow moulding, demonstrate its significant impact on enhancing plastic performance.

As industries continue to seek efficient and sustainable solutions, white masterbatch will remain a key player in driving innovation and quality in plastic production.