Masterbatch Manufacturing: Enhancing Plastics with Precision and Performance

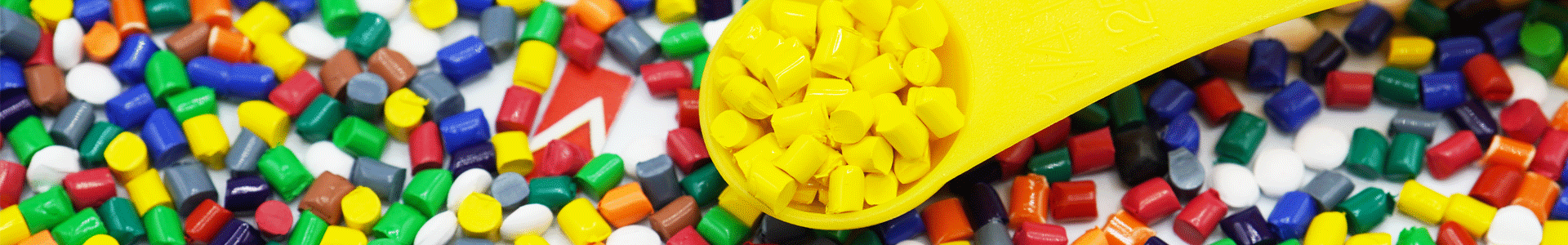

2025-03-02 01:57:44In the ever-evolving plastics industry, the masterbatch manufacturing process plays a pivotal role in enhancing the properties and aesthetics of plastic products. Masterbatch, a concentrated mixture of pigments and additives, is used to color plastics and improve their performance. This article explores the intricacies of the masterbatch manufacturing process, its methods, applications, and its significance in the plastics industry.

What is the Masterbatch Manufacturing Process?

Before diving into the details, it’s essential to understand what masterbatch is. Masterbatch is a solid or liquid additive for plastics, typically composed of pigments and additives mixed with a carrier resin. This mixture is used to color or modify the properties of plastic during production.

The Plastic Masterbatch Manufacturing Process

The masterbatch manufacturing process involves several key steps:

1. Selection of Raw Materials

The process begins with the selection of high-quality raw materials, including carrier resins, pigments, and additives. The choice of materials depends on the desired properties of the final product. For example, different pigments provide various colors, while additives enhance properties like UV stability or processing efficiency.

2. Compounding

The selected raw materials are mixed through a process called compounding. Common methods include:

-

Extrusion: Raw materials are fed into an extruder, melted, and mixed thoroughly. The molten mixture is then cooled and pelletized into granules. Extrusion is favored for its efficiency and consistent product quality.

-

Banbury Mixing: This method involves mixing raw materials in a closed chamber under heat and pressure, ideal for high-viscosity materials.

3. Cooling and Pelletizing

After compounding, the mixture is cooled to solidify it. The cooled material is then pelletized into small granules, making it easy to transport and use in further processing.

4. Quality Control

Quality control is critical in the masterbatch manufacturing process. Samples are tested for color accuracy, dispersion quality, and additive stability to ensure they meet industry standards.

What is Batch Manufacturing Process?

The batch manufacturing process involves producing a specific quantity of a product in discrete batches rather than continuously. This method offers flexibility, allowing each batch to be tailored to meet specific requirements, such as different colors or additive concentrations. This versatility is particularly beneficial in the plastics industry, where customer demands vary widely.

The Role of Masterbatch in Various Manufacturing Processes

Masterbatch is integral to several plastic manufacturing processes, enhancing the properties of the end products. Key processes include:

1. Body in White (BIW) Manufacturing Process

In the automotive industry, the BIW process involves producing the vehicle’s body before painting and assembly. Masterbatch is used in interior panels, exterior body parts, and under-the-hood components, providing desired colors and improving mechanical properties for durability and aesthetic appeal.

2. Premix Manufacturing Process

The premix process involves preparing a mixture of materials before introducing them into the main production line. Masterbatch is pre-mixed with other materials to ensure uniform color and performance, ideal for applications requiring precise color matching and property enhancement.

3. Preform Manufacturing Process

Used in bottle and container production, the preform process involves adding masterbatch to the polymer used to create preforms. These preforms are then heated and blown into their final shapes. Masterbatch enhances color, clarity, and mechanical properties like impact resistance and UV stability.

Applications of Masterbatch

Masterbatch is widely used across various industries due to its versatility and ability to enhance product performance:

-

Packaging Industry: Used in colored films, containers, and labels, masterbatch improves barrier resistance and durability while creating visually appealing packaging.

-

Consumer Goods: Enhances the color and mechanical properties of products like toys and household items, improving scratch resistance and UV stability.

-

Automotive Sector: Provides color and enhances heat resistance and durability for components exposed to harsh conditions.

-

Construction Industry: Used in pipes, roofing materials, and insulation products, improving weather resistance and aesthetics.

Advantages of Using Masterbatch

-

Cost-Effectiveness: Achieves desired colors and properties without extensive processing changes, reducing costs.

-

Consistency: Ensures high consistency in color and performance, crucial for quality control.

-

Flexibility: Customizable for various applications, meeting specific requirements efficiently.

-

Sustainability: Eco-friendly formulations support sustainability efforts in the plastics industry.

Conclusion

The masterbatch manufacturing process is a cornerstone of the plastics industry, offering vibrant colors and enhanced performance. Its applications in packaging, automotive, consumer goods, and construction demonstrate its versatility and importance. As the industry continues to evolve, masterbatch will remain a key player in driving innovation and quality in plastic production.