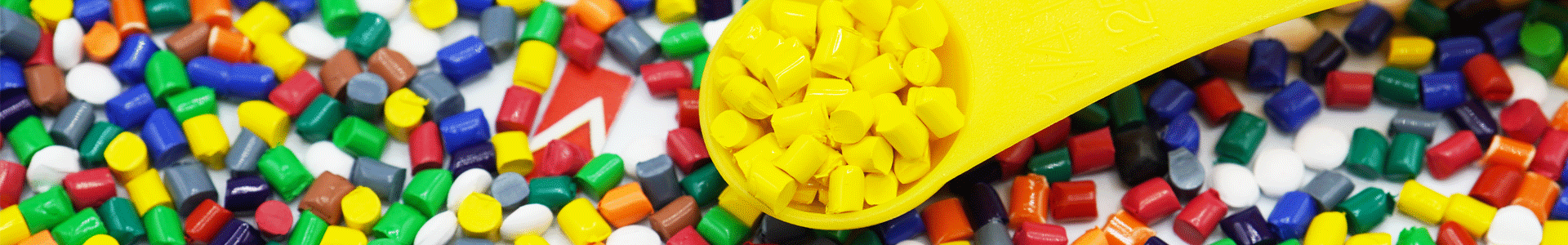

Polymer Masterbatch: The Key to Vibrant Colors and Enhanced Plastic Performance

2025-03-02 01:49:31In the plastics industry, achieving the right color and performance is crucial. Polymer masterbatch is a vital additive that not only imparts vibrant colors but also enhances the functional properties of plastic products. This article delves into what polymer masterbatch is, its manufacturing process, applications, and the benefits it offers, highlighting its indispensable role in modern plastic production.

What is Polymer Masterbatch?

Polymer masterbatch is a concentrated mixture of pigments and additives encapsulated in a polymer carrier. It is designed to add color and improve specific properties of plastic products during processing. The term “masterbatch” refers to a concentrated form that is diluted or combined with other materials in the final application.

Components of Polymer Masterbatch

-

Carrier Resin: The base material that binds pigments and additives, ensuring uniform distribution. Common carrier resins include polyethylene (PE), polypropylene (PP), and polystyrene (PS).

-

Colorants: Organic or inorganic pigments that provide color, chosen based on factors like opacity, lightfastness, and regulatory compliance.

-

Additives: Enhance properties such as UV resistance, flame retardancy, anti-static characteristics, and processing aids.

Manufacturing Process of Polymer Masterbatch

The production of polymer masterbatch involves several key steps:

1. Selection of Raw Materials

High-quality raw materials are selected based on the desired properties and end-use of the masterbatch.

2. Compounding

-

Extrusion: The most common method, where materials are heated and mixed in an extruder, then cooled and cut into granules.

-

Banbury Mixing: Ideal for high-viscosity formulations, materials are mixed under high shear and temperature in a closed chamber.

3. Cooling and Pelletizing

The mixture is cooled and pelletized into small granules for easy handling and transport.

4. Quality Control

Rigorous testing ensures color consistency, dispersion quality, and additive stability, ensuring compliance with industry standards.

Benefits of Polymer Masterbatch

-

Cost-Effectiveness: Achieves desired colors and performance without extensive processing changes, reducing production costs.

-

Consistency and Quality: Ensures high consistency in color and performance, crucial for quality control.

-

Flexibility: Can be tailored for various applications, meeting specific requirements efficiently.

-

Environmental Sustainability: Eco-friendly formulations using recycled or bio-based components support sustainability efforts.

Applications of Polymer Masterbatch

Polymer masterbatch is used across various industries, including packaging, automotive, consumer goods, and construction, to enhance both aesthetics and functionality.

Conclusion

Polymer masterbatch is a cornerstone of the plastics industry, offering vibrant colors and enhanced performance. Its versatility, cost-effectiveness, and sustainability make it an essential tool for manufacturers aiming to meet the demands of modern plastic production.