Masterbatch Blue: Revolutionizing Color Solutions in the Plastics Industry

2025-03-02 01:47:10Masterbatch Blue: A Comprehensive Guide to Its Composition, Applications, and Innovations

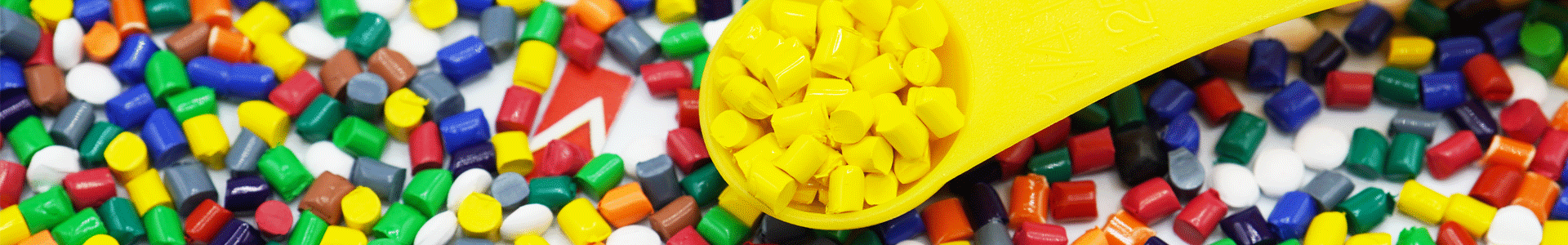

Masterbatch blue is a specialized additive widely used in the plastics industry to impart a vibrant blue color to various plastic products. By embedding high concentrations of blue pigment within a carrier resin, masterbatch blue ensures consistent, long-lasting coloration. Unlike liquid or powdered colorants, which may disperse unevenly, masterbatch blue offers superior color consistency, heat resistance, and ease of use, making it the preferred choice for manufacturers across multiple sectors.

This article explores the composition, applications, benefits, and recent innovations in blue masterbatch technology.

What is Masterbatch Blue?

Masterbatch blue is a concentrated mixture of blue pigments combined with a base polymer, known as the carrier resin. The carrier resin is selected based on compatibility with the target polymer to ensure effective color dispersion. The primary components of masterbatch blue include:

-

Pigments: Blue pigments are chosen for their vibrancy, durability, and lightfastness, ensuring the color remains strong even under prolonged exposure to light and temperature changes.

-

Carrier Resin: Typically, the carrier resin is either the same polymer or compatible with the material to be colored. Common choices include polyethylene, polypropylene, or polystyrene.

-

Additives: Additional additives, such as stabilizers, UV inhibitors, or processing aids, may be included to enhance performance based on the end-use application.

Manufacturing Process of Blue Masterbatch

The production of masterbatch blue involves several precise steps to ensure color consistency and quality:

-

Pigment Preparation: High-quality blue pigments are processed to achieve the desired particle size, ensuring consistent dispersion.

-

Compounding: Pigments are mixed with the carrier resin in high-shear mixers or twin-screw extruders to ensure thorough dispersion.

-

Pelletizing: The mixture is extruded into thin strands and cut into small, uniform pellets, ready for use in manufacturing processes.

-

Quality Control: Each batch undergoes rigorous quality checks to ensure it meets industry standards for color consistency, particle distribution, and overall quality.

Types of Blue Pigments Used

Different types of pigments are used depending on the desired shade, properties, and cost-effectiveness:

-

Phthalocyanine Blue (PB15): Offers a bright, intense color with excellent heat stability and resistance to fading.

-

Ultramarine Blue: Known for its vivid, deep hue, though less stable in acidic environments.

-

Cobalt Blue: Provides exceptional stability and unique color properties, ideal for specialized applications.

-

Organic and Inorganic Blends: Used to achieve unique color properties and enhanced performance characteristics, such as improved UV resistance.

Applications of Masterbatch Blue

Masterbatch blue has versatile applications across a range of industries:

-

Packaging Industry: Used in bottles, caps, and containers for visual appeal and brand recognition.

-

Textile and Fiber Industries: Enhances colorfastness in fabrics and fibers.

-

Agricultural Products: Adds color differentiation and UV protection to agricultural films.

-

Automotive and Construction Materials: Provides long-lasting color for components like pipes, panels, and fittings.

-

Consumer Goods: Used in household containers, toys, and other everyday items for aesthetic appeal and safety.

Benefits of Using Masterbatch Blue

-

Cost Efficiency: Achieves desired color intensity with smaller quantities, reducing material costs.

-

Ease of Use: Pellet form minimizes mess and allows for precise dosing.

-

Color Consistency: Ensures uniform coloration across large production runs.

-

Enhanced Stability: Resists fading under heat, light, and weather conditions.

-

Improved Processability: Enhances flow, reduces shrinkage, and improves dimensional stability.

Recent Trends in Blue Masterbatch Technology

-

Bio-Based Masterbatches: Compatible with biodegradable and bio-based resins, reducing environmental impact.

-

Enhanced UV Resistance: Maintains color in applications exposed to direct sunlight.

-

Nano-Pigments: Improve dispersion, resulting in more vivid colors and better durability.

-

Recycled Content Masterbatch: Supports the circular economy by using recycled resins.

-

Customization Options: Tailored solutions for unique shades, durability, and specialized functionality.

Conclusion

Masterbatch blue is a vital tool in the plastics industry, offering vibrant, consistent coloration and enhanced performance across various applications. From packaging and textiles to automotive and consumer goods, its versatility and benefits make it indispensable for manufacturers.

As the industry evolves, innovations such as bio-based masterbatches, nano-pigments, and recycled content options are driving sustainability and performance. By leveraging these advancements, manufacturers can meet the growing demand for high-quality, eco-friendly plastic products.