Driving Innovation: The Role of Color Masterbatch in Automotive Manufacturing

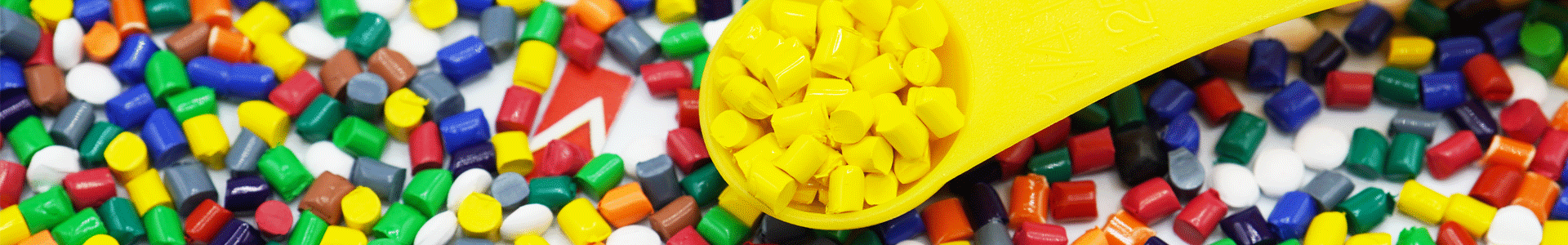

2025-02-28 22:50:05Color masterbatch has become a critical component in the automotive industry, significantly impacting the production of vehicles and automotive parts. Its role extends beyond aesthetics, contributing to durability, cost efficiency, and overall performance. In 2022, plastics accounted for approximately 14% of the materials used in vehicle manufacturing, and this percentage is expected to rise as manufacturers focus on reducing vehicle weight and improving fuel efficiency.

This article delves into the applications, benefits, and essential properties of color masterbatch in the automotive sector, highlighting why it has become a decisive element in modern vehicle production.

Applications of Color Masterbatch in the Automotive Industry

Color masterbatch is widely used in the automotive industry to enhance both the visual appeal and functional performance of various components. Key applications include:

1. Bumpers and Grilles

Color masterbatch ensures a consistent and durable finish for bumpers and grilles, which are exposed to environmental factors such as UV radiation and physical impacts.

2. Side Mirrors and Door Handles

These components benefit from color masterbatch by achieving a uniform color scheme while offering resistance to UV radiation and scratches, especially when combined with specialized additives.

3. Body Panels

Color masterbatch is used in plastic body panels to provide vibrant and uniform colors, enhancing the vehicle’s overall aesthetic appeal.

4. Dashboards

Dashboards require both visual appeal and durability. Color masterbatch helps create surfaces that resist fading and damage, ensuring long-lasting quality.

5. Trims

Interior and exterior trims are often customized with specific colors and textures using color masterbatch, ensuring consistency and durability across all parts.

6. Lighting

Color masterbatch is used in headlight and taillight housings, as well as interior ambient lighting, to create specific color effects and improve visibility.

Benefits of Using Color Masterbatch in the Automotive Industry

Color masterbatch offers numerous advantages that make it indispensable in automotive manufacturing:

1. Enhanced Aesthetics

-

Vibrant Colors: Ensures automotive parts maintain vibrant and consistent colors, crucial for maintaining the vehicle’s visual appeal.

-

Customization: Allows manufacturers to create custom colors that align with brand identity, such as Ferrari’s iconic red.

-

Surface Finish: Contributes to a smooth and glossy surface finish, enhancing the overall aesthetic quality of visible components like dashboards and door panels.

2. Durability and Performance

-

UV Protection: UV stabilizers in color masterbatch protect plastic components from sunlight, preventing color fading and material degradation.

-

Heat Resistance: Heat-resistant pigments and additives ensure colors remain stable under high temperatures, common in automotive environments.

-

Scratch Resistance: Additives like colloidal silica and mineral fillers enhance scratch and mar resistance, particularly important for interior parts.

Key Properties of Color Masterbatch for Automotive Applications

When selecting color masterbatch for automotive use, several factors must be considered to ensure optimal performance:

1. Color Consistency

Even distribution of pigments throughout the polymer is essential to achieve uniform color across all parts.

2. Color Matching

Advanced color matching capabilities are crucial to meet specific brand identity requirements. Partnering with a trusted manufacturer ensures precise color replication.

3. Mechanical and Performance Properties

Depending on the application, additives such as UV stabilizers, thermal stabilizers, and cleaning agents can be incorporated to enhance the performance of the final product.

Conclusion

Color masterbatch plays a vital role in the automotive industry, significantly impacting both the aesthetics and performance of vehicles. From enhancing visual appeal to improving durability and resistance to environmental factors, its applications are diverse and essential.

As the automotive industry continues to evolve, the demand for high-quality color masterbatch will grow, driven by the need for lightweight, durable, and visually appealing materials. By understanding its benefits and key properties, manufacturers can leverage color masterbatch to create vehicles that stand out in a competitive market.

For reliable and high-quality color masterbatch solutions, partnering with a trusted supplier is essential to ensure consistency, performance, and compliance with industry standards.