Color Masterbatch Demystified: Applications, Production, and Key Advantages

2025-02-28 22:49:54Color Masterbatch: A Comprehensive Guide to Applications, Production, and Benefits

In the dynamic world of plastics, color plays a pivotal role in determining a product's success, influencing aesthetics, user experience, and brand recognition. Color masterbatch, a specialized polymer colorant, has emerged as a key solution for achieving precise and vibrant colors in plastic products. This guide explores the essentials of color masterbatch, its applications, production process, and the benefits it offers to various industries.

What is Color Masterbatch?

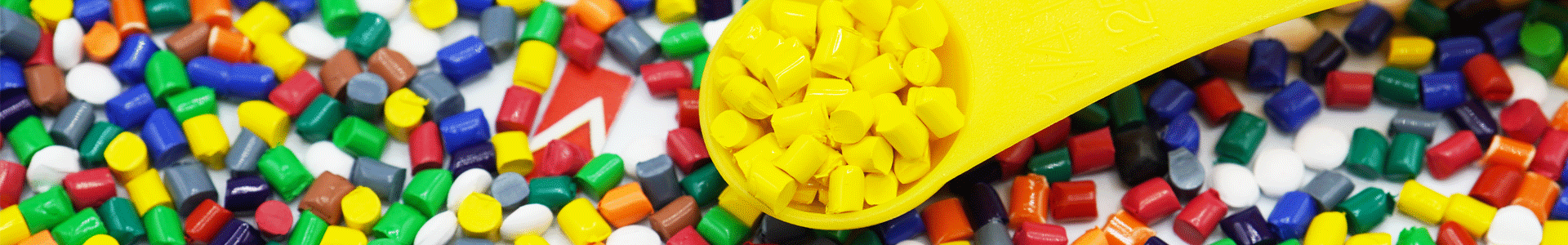

Color masterbatch, also known as color concentrate, is a granular mixture of pigments encapsulated in a carrier resin, typically polyethylene (PE) or polypropylene (PP). It is used to impart consistent and vibrant colors to raw polymers during the manufacturing process. Due to its ability to deliver precise color matching and enhance product appeal, color masterbatch has become an indispensable tool in the plastics industry.

The global color masterbatch market was valued at USD 4.65 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.5% through 2031. This growth is driven by increasing demand for visually appealing and high-performance plastic products across various sectors.

Common Applications of Color Masterbatch

Color masterbatch is widely used across multiple industries due to its ability to enhance visual appeal, ensure color consistency, and support brand recognition. Key applications include:

1. Packaging

Color masterbatch is extensively used in packaging materials such as bottles, containers, films, bags, and flexible packaging. Its ability to deliver vibrant and consistent colors makes it ideal for consumer-facing products.

2. Automotive

In the automotive industry, color masterbatch is used to produce interior and exterior components, including dashboards, bumpers, and trims. Its aesthetic appeal and durability are critical for meeting industry standards.

3. Consumer Goods

From toys and electronics to household appliances, color masterbatch enables easy customization and vibrant finishes, enhancing the visual appeal of consumer products.

4. Medical Devices

In the medical field, color masterbatch is used to improve the visibility and safety of devices, ensuring clear differentiation and ease of use for medical professionals.

5. Construction

Color masterbatch is used in construction materials such as pipes, fittings, panels, and profiles. Its compatibility with additives enhances the properties of end products, making them more durable and functional.

How is Color Masterbatch Produced?

The production of color masterbatch involves several key steps to ensure high-quality and consistent results:

1. Material Preparation

The process begins with selecting the appropriate carrier resin (typically PE or PP) and high-quality pigments. Additives, such as UV stabilizers, may also be included to enhance specific properties.

2. Mixing and Extrusion

The pigments and carrier resin are thoroughly mixed to ensure even dispersion. The mixture is then melted and extruded through an extruder to form continuous masterbatch strips.

3. Cooling and Granulation

The extruded strips are cooled and solidified before being cut into uniform granules of the desired size and shape.

4. Screening and Inspection

The final granules undergo rigorous screening and inspection to ensure quality and consistency. Techniques such as spectrophotometry and melt flow index (MFI) testing are used to verify color accuracy and processing performance.

Key Considerations for Producing Color Masterbatch

Producing high-quality color masterbatch requires attention to several critical factors:

1. Pigment Selection

Choose pigments with excellent dispersibility, lightfastness, and heat stability to ensure vibrant and consistent colors.

2. Carrier Resin Compatibility

The carrier resin must be compatible with the base polymer of the final product to ensure uniform dispersion and avoid processing issues.

3. Production Parameters

Optimize parameters such as temperature, pressure, and mixing speed to achieve even dispersion and efficient production.

4. Quality Control

Implement robust quality control measures, including spectrophotometry and MFI testing, to ensure the masterbatch meets required specifications.

5. Regulatory Compliance

Ensure the masterbatch complies with industry standards and regulations, particularly for applications in food packaging and medical devices.

Top Benefits of Using Color Masterbatch

Color masterbatch offers numerous advantages that make it a preferred choice for plastic manufacturers:

1. Consistent Color Dispersion

High-quality color masterbatch ensures uniform color distribution, reducing the risk of streaks or color variations.

2. Enhanced Visual Appeal

Vibrant and intense colors enhance the aesthetic appeal of products, making them more attractive to consumers.

3. Customization

Advanced technologies like spectrophotometry and computer-aided color matching (CACM) enable precise color matching to meet specific requirements.

4. Cost-Effectiveness

Using color masterbatch is more economical than pre-colored polymers, reducing material costs and waste.

5. Ease of Use

Color masterbatch granules are easy to handle and process, simplifying manufacturing operations.

6. Brand Recognition

Color is a powerful marketing tool, and color masterbatch helps companies create distinctive packaging and products that resonate with consumers.

7. Production Efficiency

Color masterbatch streamlines production processes, reducing waste and improving overall efficiency.

Conclusion

Color masterbatch is a vital component in the plastics industry, offering a wide range of benefits that enhance product performance, aesthetics, and brand recognition. From packaging and automotive parts to consumer goods and medical devices, its applications are diverse and impactful.

As the demand for high-quality, visually appealing plastics continues to grow, color masterbatch will remain a key driver of innovation and efficiency in the industry. By understanding its production process, applications, and benefits, manufacturers can leverage color masterbatch to create products that stand out in a competitive market.

For reliable and high-quality color masterbatch, partnering with a trusted supplier is essential to ensure consistency, performance, and compliance with industry standards.